When our managing director gets into his car on a cold winter morning, he wants to move the seat backwards. He is startled when he touches it. He abruptly pulled back his hand as he touched the lever. The metal part was cold as ice. This would not have happened if it were made of plastic, he thought to himself.

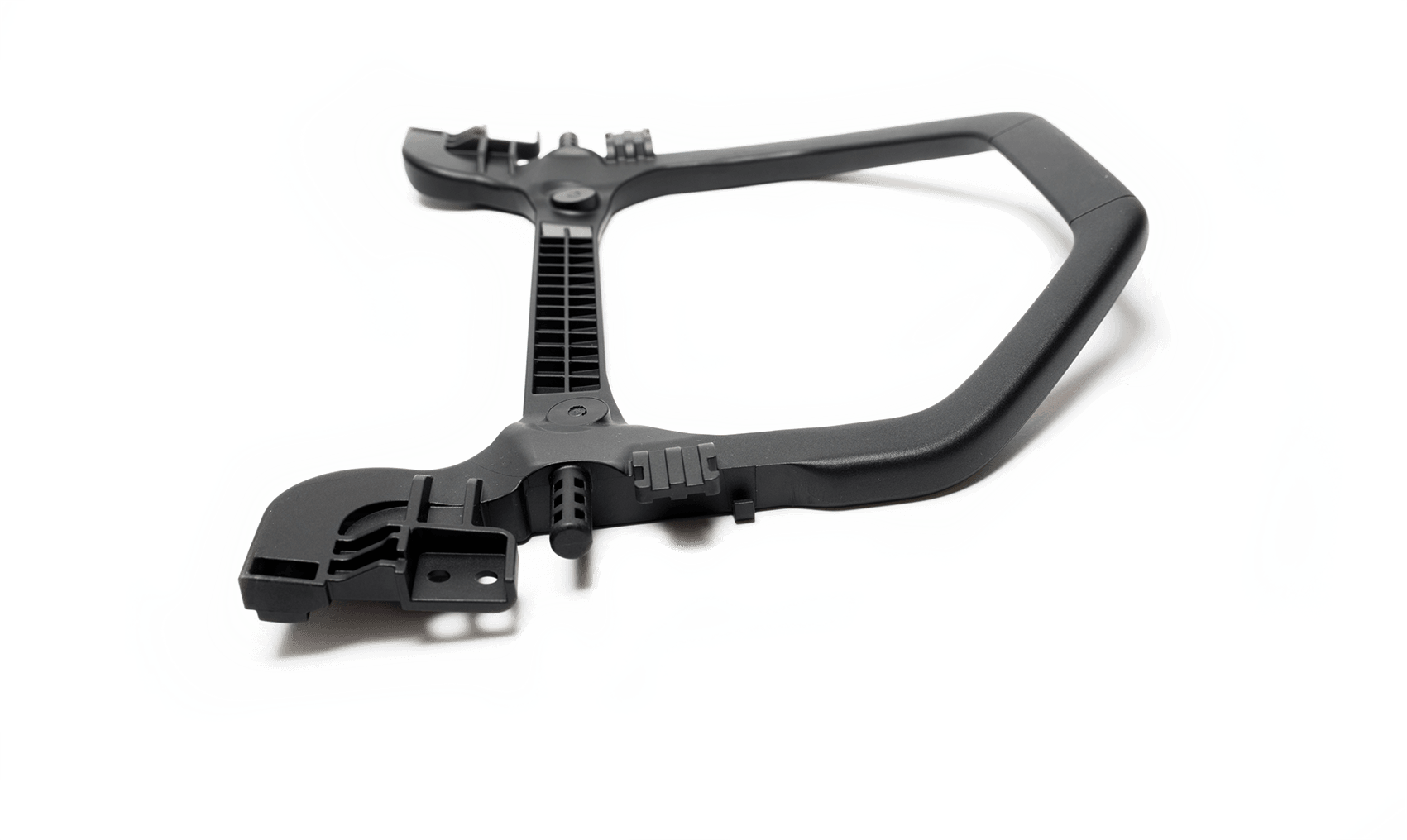

After arriving at the office, he tasked the development department with the problem. The engineers worked meticulously to develop a lever from plastic and tested the construction in two different injection molding processes – with gas-assisted injection and water injection. The tests were so successful that Müller-Technik issued a patent for the concept.

Approximately ten years later the time had come. Serial production for the first seat lever from plastic began. Volkswagen realized the benefits of a plastic lever. From 2014 on, the levers have been installed in the family vans of the second largest automaker in the world ensuring that he and many other drivers will not get cold hands in winter.

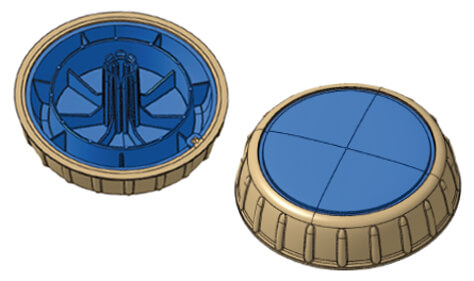

Müller-Technik reconciles opposites. A handwheel on a car seat must be able to withstand a lot. At the same time, it should feel good in the hand of the driver. It must be pleasant to touch. And, finally, it must not cost too much.

Our solution: 2C handwheels. Previously, an automaker had to assemble three injection molding parts – the abrasive ring, handwheel and ring – in a laborintensive process while the new component can be completed in one work step. Both components are molded and joined in one injection molding machine, which saves time and money.

The ring consists of a softer more pleasant material than the handwheel whose primary purpose is to withstand strong forces. Incidentally, 2 or 3-component parts have a significantly longer service life than products assembled from multiple components.

Parents with children know about the practical safety system Isofix. Child seats can be attached especially securely at two hooks that have been integrated into the seat. Müller-Technik makes sure that mom and dad can easily find the Isofix connection in the Audi A3: by providing a printed cover cap. The lettering “Top Tether” (the name of the Isofix system) and a symbol are visible.

The component is rather inconspicuous and could be easily produced if not for the lettering and the symbol that are printed at various levels of the component – once on the profile and once on the inside. Our developers had to put their heads together until they constructed a suitable fully automatic pad print for this part.

Pad printing is an indirect printing process in which the color is transferred through an elastic pad made of silicone rubber from the print form to the plastic part.